Inventory automation with proactive stock alerts

Multistep workflow

The problem:

Managing material inventory and production scheduling relied on multiple manually updated spreadsheets that were difficult to keep in sync. CRM orders required manual processing, inventory deductions were done by hand, and stock levels often became mismatched. This caused missed reorder points, slowed fulfillment, and made it hard to confidently schedule new sales orders, increasing the risk of overselling or production delays.

The solution:

A fully integrated Google Workspace automation connected the CRM order log, raw material inventory, and production dashboard. Using Google Apps Script, newly placed orders automatically trigger stock deductions, populate the production dashboard, and flag low-stock or oversold materials. Dynamic formulas and R1C1 logic validate inventory and production readiness. Automated email alerts notify purchasing teams, while manual stock updates remain fully supported.

The benefits:

Eliminated manual cross-referencing between CRM, inventory, and production trackers

Automatically deducted stock levels and created production-ready records for each new order

Flagged insufficient inventory and reorder needs in real time

Improved accuracy and confidence in scheduling production runs

Reduced administrative overhead and potential human error

Created a scalable automation foundation for future system expansion

The only manual step, an input data sheet logs incoming orders—SKU, quantity, customer, and ship date. Newly placed orders entries trigger automated inventory updates and syncs all elements of the tool.

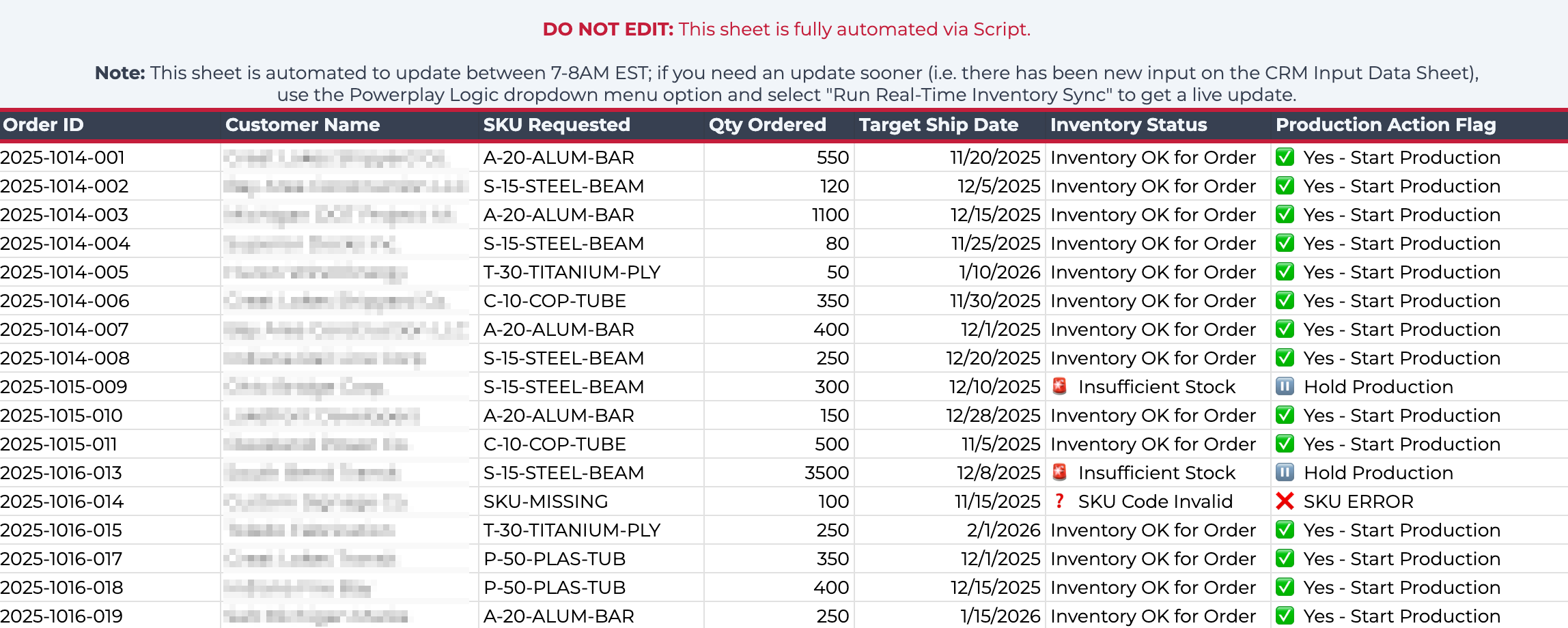

Automated production dashboard

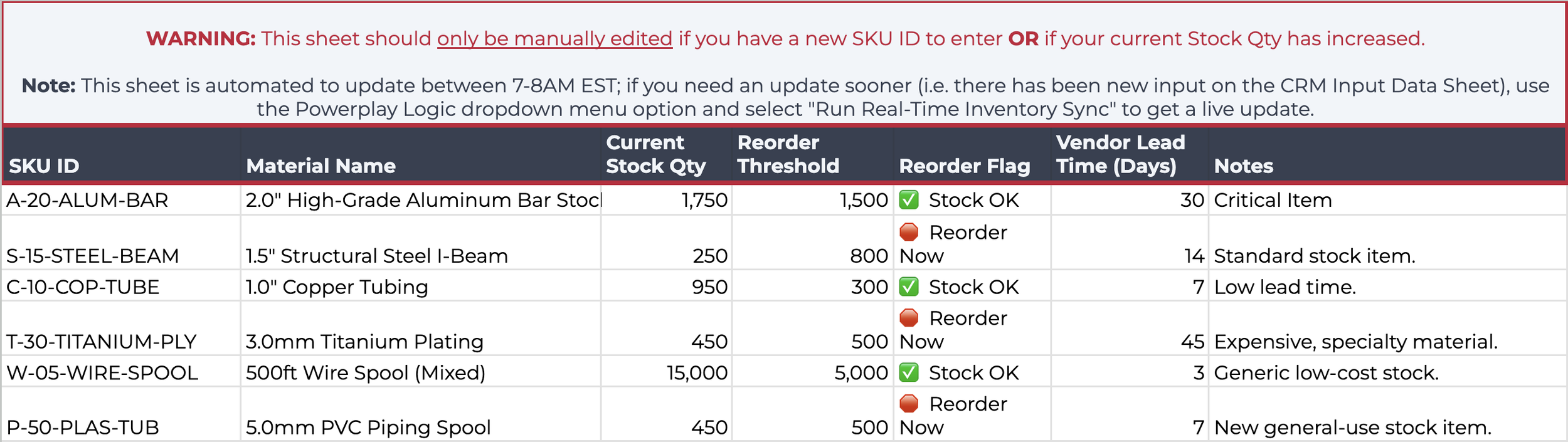

A raw material inventory tracks SKU, current stock, and reorder thresholds, updating automatically with CRM orders to maintain accurate, real-time inventory levels.

Automated raw material inventory

The production dashboard sheet autopopulates with new orders, showing SKU, customer, quantity, ship date, inventory status, and production readiness for real-time workflow visibility.

Automated production dashboard

Proactive email alerts

Automated email alerts notify purchasing teams in real time when stock is low or oversold, enabling immediate action to reorder materials and prevent production delays.

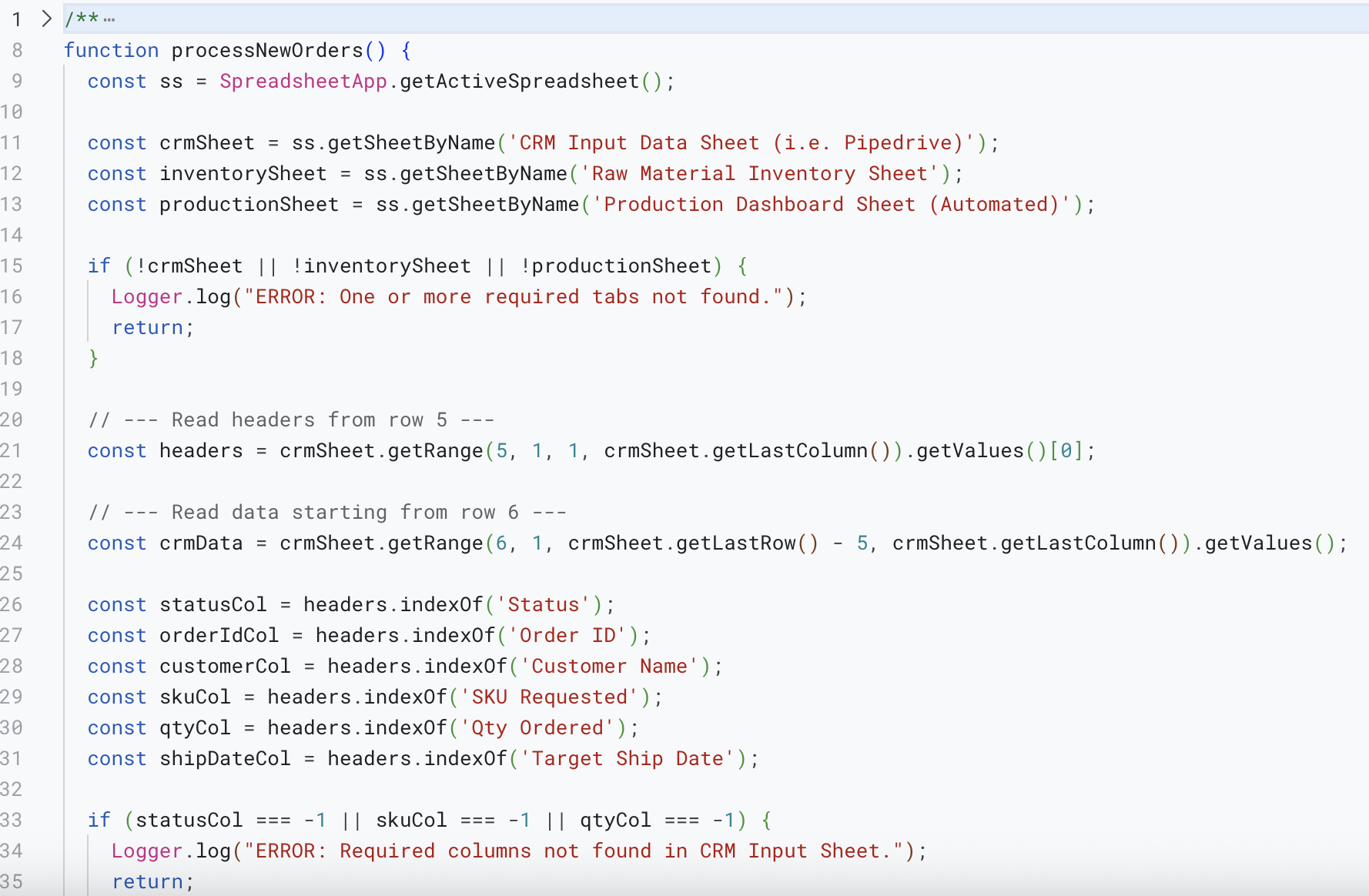

JavaScript

Automates end-to-end order and inventory management using Google Apps Script. The system reads CRM data, processes “Order Placed” rows, and updates live stock levels in the Raw Material Inventory Sheet via getRange(), getValue(), and setValue(). Using dynamic VLOOKUP formulas, it syncs production readiness data in real time. It also leverages MailApp.sendEmail() for low-stock alerts and SpreadsheetApp.getUi() to add a custom “Run Real-Time Inventory Sync” menu for manual triggers.